Product Description

Product Description

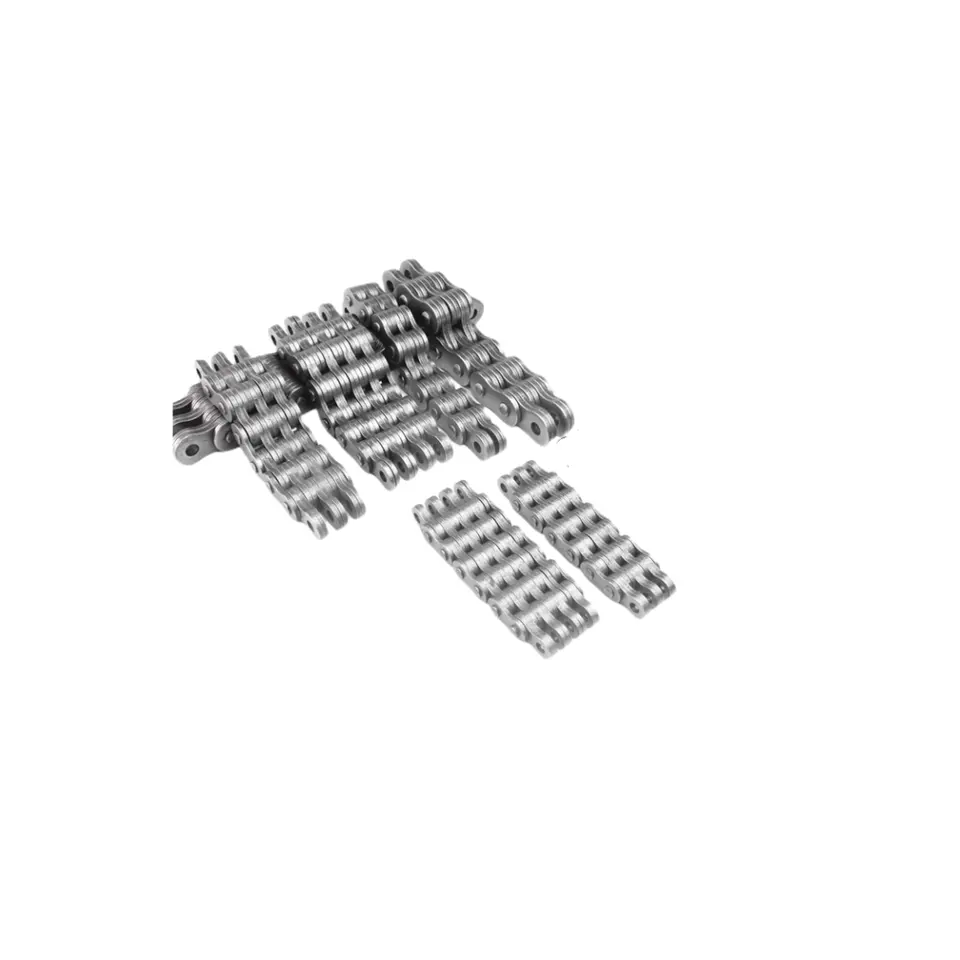

AL Series leaf chains are manufactured in accordance with ANSI leaf chain specification dimensions and are considered to be the modern-day “lighter” duty of leaf chains. AL leaf chains were the first series of ANSI leaf chains around and are still utilized today in many lifting applications due to the space-saving high-strength lifting design and nature of this chain. What puts our selection of leaf chains in another class of their own is the utilization of high-strength hardened pins, heat-treated plates, and shot-peened components. The chain is also factory pre-stressed to reduce initial install stretching.

Product Parameters

AL Series Leaf Chains Size Chart

| Chain Size | Lacing | Pitch (P) | Min. Tensile Strength | Weight (Per Ft) | Pin Diameter (D) | Pin Length (L) | Plate Height | Plate Thickness (T) |

|---|---|---|---|---|---|---|---|---|

| AL322 | 2X2 | 0.375″ | 2,045 lbs | 0.2 lbs | 0.141″ | 0.27″ | 0.30″ | 0.051″ |

| AL344 | 4X4 | 0.375″ | 4,090 lbs | 0.3 lbs | 0.141″ | 0.46″ | 0.30″ | 0.051″ |

| AL422 | 2X2 | 0.500″ | 3,205 lbs | 0.3 lbs | 0.156″ | 0.33″ | 0.41″ | 0.059″ |

| AL444 | 4X4 | 0.500″ | 6,409 lbs | 0.5 lbs | 0.156″ | 0.57″ | 0.41″ | 0.059″ |

| AL466 | 6X6 | 0.500″ | 9,614 lbs | 0.8 lbs | 0.156″ | 0.81″ | 0.41″ | 0.059″ |

| AL522 | 2X2 | 0.625″ | 5,000 lbs | 0.4 lbs | 0.200″ | 0.44″ | 0.50″ | 0.080″ |

| AL534 | 3X4 | 0.625″ | 7,500 lbs | 0.7 lbs | 0.200″ | 0.67″ | 0.50″ | 0.080″ |

| AL544 | 4X4 | 0.625″ | 10,000 lbs | 0.8 lbs | 0.200″ | 0.76″ | 0.50″ | 0.080″ |

| AL566 | 6X6 | 0.625″ | 15,000 lbs | 1.2 lbs | 0.200″ | 1.08″ | 0.50″ | 0.080″ |

| AL622 | 2X2 | 0.750″ | 8,409 lbs | 0.6 lbs | 0.234″ | 0.51″ | 0.61″ | 0.095″ |

| AL644 | 4X4 | 0.750″ | 14,450 lbs | 1.2 lbs | 0.234″ | 0.89″ | 0.61″ | 0.095″ |

| AL666 | 6X6 | 0.750″ | 22,750 lbs | 1.8 lbs | 0.234″ | 1.27″ | 0.61″ | 0.095″ |

| AL688 | 8X8 | 0.750″ | 30,317 lbs | 2.4 lbs | 0.234″ | 1.66″ | 0.61″ | 0.095″ |

| AL822 | 2X2 | 1.000″ | 12,886 lbs | 1.0 lbs | 0.312″ | 0.63″ | 0.81″ | 0.128″ |

| AL844 | 4X4 | 1.000″ | 25,773 lbs | 2.0 lbs | 0.312″ | 1.16″ | 0.81″ | 0.128″ |

| AL866 | 6X6 | 1.000″ | 38,636 lbs | 3.0 lbs | 0.312″ | 1.74″ | 0.81″ | 0.128″ |

| AL1571 | 2X2 | 1.250″ | 20,114 lbs | 1.6 lbs | 0.375″ | 0.77″ | 1.01″ | 0.157″ |

| AL1044 | 4X4 | 1.250″ | 40,227 lbs | 3.1 lbs | 0.375″ | 1.43″ | 1.01″ | 0.157″ |

| AL1066 | 6X6 | 1.250″ | 60,227 lbs | 4.8 lbs | 0.375″ | 2.06″ | 1.01″ | 0.157″ |

| AL1088 | 8X8 | 1.250″ | 80,454 lbs | 6.7 lbs | 0.375″ | 2.70″ | 1.01″ | 0.157″ |

| AL1222 | 2X2 | 1.500″ | 28,864 lbs | 2.5 lbs | 0.437″ | 0.96″ | 1.20″ | 0.189″ |

| AL1244 | 4X4 | 1.500″ | 57,727 lbs | 4.7 lbs | 0.437″ | 1.72″ | 1.20″ | 0.189″ |

| AL1266 | 6X6 | 1.500″ | 86,591 lbs | 7.1 lbs | 0.437″ | 2.49″ | 1.20″ | 0.189″ |

| AL1288 | 8X8 | 1.500″ | 115,450 lbs | 9.4 lbs | 0.437″ | 3.25″ | 1.20″ | 0.189″ |

| AL1444 | 4X4 | 1.750″ | 84,705 lbs | 7.0 lbs | 0.498″ | 2.02″ | 1.43″ | 0.220″ |

| AL1466 | 6X6 | 1.750″ | 127,045 lbs | 10.2 lbs | 0.498″ | 2.94″ | 1.43″ | 0.220″ |

| AL1644 | 4X4 | 2.000″ | 107,045 lbs | 8.7 lbs | 0.559″ | 2.28″ | 1.64″ | 0.252″ |

| AL1666 | 6X6 | 2.000″ | 160,454 lbs | 13.3 lbs | 0.559″ | 3.30″ | 1.64″ | 0.252″ |

| AL1688 | 8X8 | 2.000″ | 214,090 lbs | 17.1 lbs | 0.559″ | 4.31″ | 1.64″ | 0.252″ |

Company Profile

The company has advanced manufacturing technology and relatively strong manufacturing force, and high-end precision testing instruments to ensure that every chain leaving the factory is qualified. The company mainly deals in: transmission chain, transmission chain, lifting chain, agricultural machinery chain, stainless steel chain, etc. Various non-standard chains are ordered separately. The company uses more than 600 kinds of non-standard molds. It can be customized according to drawings. We implement all-round management and control over product quality and service, and constantly improve customer satisfaction. The chain produced by the company enjoys a certain reputation in the world with its high quality, good reputation and high-quality service.

Related products

The chain types are divided into engineering chain, conveying chain, plate chain, transmission chain, escalator chain, parking equipment chain, agricultural chain, stainless steel chain, etc. There are different types of chains with different purposes, specifications, models and styles.

| Plate chain type Plate chain is usually used to lift goods. For example, forklift, lifting machinery and equipment. Plate chain has no rollers, but chain plates are connected with each other. It is a kind of chain used for loading. Different types of plate chains have different functions, | Stainless steel chain Stainless steel chain types include standard stainless steel chain, stainless steel hollow pin chain, stainless steel chain used for environmental protection equipment, etc, |

| Type of transmission chain Many types of transmission chains are power transmission chains, such as precision roller chains, double pitch roller chains, high-strength short pitch precision roller chains, petroleum chains, pumping unit chains, self-lubricating roller chains, side bending (turning machine) chains, corrosion resistant chains, etc | There are many types of escalator chains, including escalator step chains, heavy-duty high gradient escalator step chains, travelator chains, and escalator chains of different specifications and models,

|

| The engineering chain includes many kinds of chains, such as cement bucket elevators, environmental protection equipment, pavers, trenchers, welding equipment, mining, power plant dust removal and other equipment. |

Agricultural machinery chain Agricultural machinery chain is a chain developed and produced according to the characteristics of different crops, including rice harvester chain, GS38 combine chain, corn harvester chain, citrus straw harvester chain, soybean harvester chain, peanut harvesting chain, garlic sowing chain, and potato planter chain. |

| There are many types of conveying chains, such as wood conveying chain, double speed chain, RF conveying chain, sharp tooth chain, sugar chain, brown oil chain, F chain, metric conveying chain, top roller conveying chain, grain scraper, hollow pin, suspension conveying, etc. The conveying chain is a power chain for transporting goods. | Parking equipment chain This type of chain includes roller chains for parking equipment, chains for vertical circulation parking equipment, and parking equipment chains that can be developed according to demand. |

We not only produce chains and transmissions, including gear boxes, sprockets, gears, racks, couplings and other products, but also supply them to meet your one-stop purchase. Welcome to consult us

Packaging & Shipping

Certifications

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Transmission Chain, Drag Chain, Conveyor Chain, Dedicated Special Chain |

|---|---|

| Material: | Iron |

| Surface Treatment: | Oil Blooming |

| Feature: | Oil Resistant |

| Chain Size: | 1/2"*3/32" |

| Structure: | Roller Chain |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What are the environmental considerations when using leaf chains?

When using leaf chains, several environmental factors should be taken into account to ensure optimal performance and longevity:

1. Temperature and Weather Conditions: Leaf chains may be exposed to a wide range of temperatures, from extreme cold to high heat. Adequate lubrication and material selection are essential to prevent chain failure in extreme weather conditions.

2. Corrosion and Chemical Exposure: In environments with high humidity, moisture, or chemical exposure, leaf chains may be susceptible to corrosion and degradation. Choosing corrosion-resistant materials and regular maintenance can mitigate these effects.

3. Contaminants and Dust: Dust, dirt, and other contaminants can accumulate on the chain, leading to accelerated wear and reduced performance. Regular cleaning and lubrication are vital to prevent premature failure.

4. Load and Usage Patterns: Consider the load capacity and usage patterns of the chain in the specific environment. Heavy loads, continuous operation, and shock loads can impact the chain’s wear rate and fatigue life.

5. Environmental Regulations: Some applications, such as those in the food or pharmaceutical industries, may have strict regulations regarding the materials and lubricants used in the chains to ensure they are safe for use in such environments.

6. Noise and Vibration: Certain environments may have noise and vibration restrictions. Proper chain maintenance and lubrication can help reduce noise levels and vibration.

7. Sustainability: Consider the environmental impact of chain materials and lubricants used. Opt for environmentally friendly options when possible to promote sustainability.

Overall, understanding the environmental conditions and selecting the appropriate chain materials and lubrication are crucial to ensure leaf chains perform optimally and have an extended service life in various applications. Regular inspection, maintenance, and compliance with environmental regulations will contribute to safe and efficient chain operation while minimizing the impact on the surrounding environment.

What are the benefits of using a leaf chain in power generation plants?

Leaf chains offer several advantages when used in power generation plants:

- High Strength: Leaf chains are designed to handle heavy loads and provide high tensile strength, making them suitable for lifting and load-bearing applications commonly found in power generation plants.

- Reliability: These chains are known for their durability and reliability, ensuring smooth and consistent operation even in demanding environments, which is crucial for maintaining the efficiency and safety of power generation equipment.

- Shock Absorption: Leaf chains have the ability to absorb shocks and dynamic forces, which is essential in power generation applications where sudden changes in load and pressure can occur during the operation of turbines, generators, and other equipment.

- Compact Design: Leaf chains offer a compact and lightweight design, allowing them to be used in confined spaces and complex machinery setups commonly found in power generation plants.

- Easy Installation: The simple design of leaf chains makes them easy to install and maintain, reducing downtime and ensuring efficient plant operation.

- Cost-Effectiveness: Leaf chains are cost-effective compared to other heavy-duty lifting solutions, providing a reliable and long-lasting solution without compromising on performance.

- Resistance to Harsh Environments: Power generation plants often operate in challenging environments, including high temperatures, humidity, and exposure to chemicals. Leaf chains are designed to withstand these conditions, making them suitable for use in such settings.

In summary, the use of leaf chains in power generation plants can offer benefits such as high strength, reliability, shock absorption, compact design, easy installation, cost-effectiveness, and resistance to harsh environments. These features make leaf chains a favorable choice for various lifting and load-bearing applications within power generation facilities.

editor by CX 2024-01-02